Marinate App

Tablet dashboard (iOS) solving for communication gaps in food production operations

Type: Passion passion project based on past job at Marinate (Name changed for privacy reasons)

Timeline: 10 months (self taught with mentor feedback)

Goal: Identify problems & opportunities within the production process to solve and improve the Operation team’s efficiency

Background

The Company

Marinate is a wellness brand focused on clean meal prep delivered to busy working professionals. The core product is whole food meals cooked, packaged and delivered to your door 2x per week.

*Name changed for privacy reasons

Background

Production Process & Players

Here’s a high overview of the production process and who is involved in each stage so you can better understand what I built

End Result

What I Built

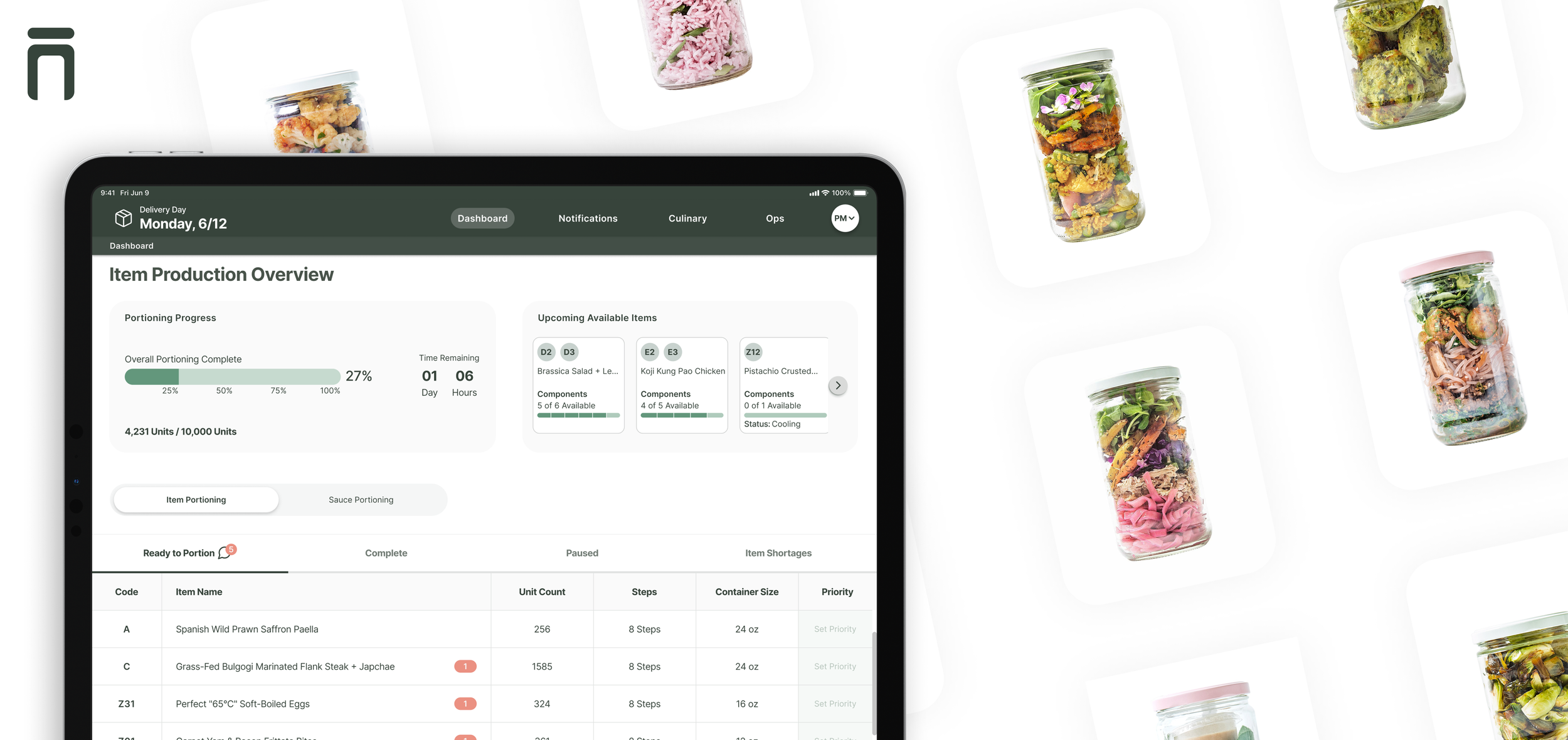

The Marinate App is a dashboard and planning tool, used internally by Ops Leads & Chefs to collect and share ‘near real-time’ information about food production.

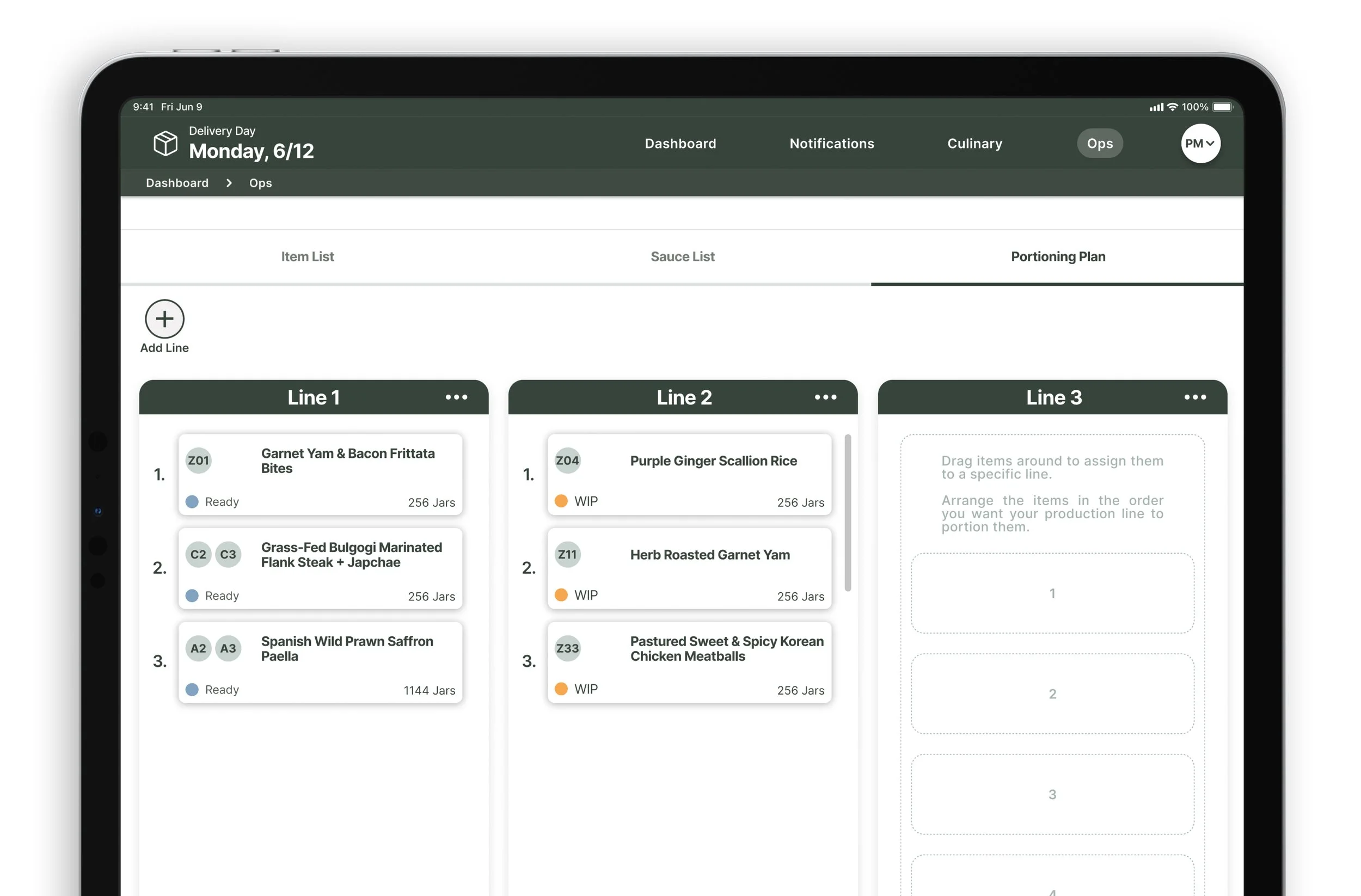

Ops Leads can build and manage production plans for each production line to better visualize what items each line will be working on.

Features:

• Add Items to a production line (more on this later)

• Change the order that items will be portioned in on a particular production line

• Move Items to other production lines

• Add additional production lines

Ops Leads can communicate production notes and tasks to other shifts instead of leaving scattered notes across different communication channels (paper & digital).

Initial Problem Exploration

Where the Problem Started…

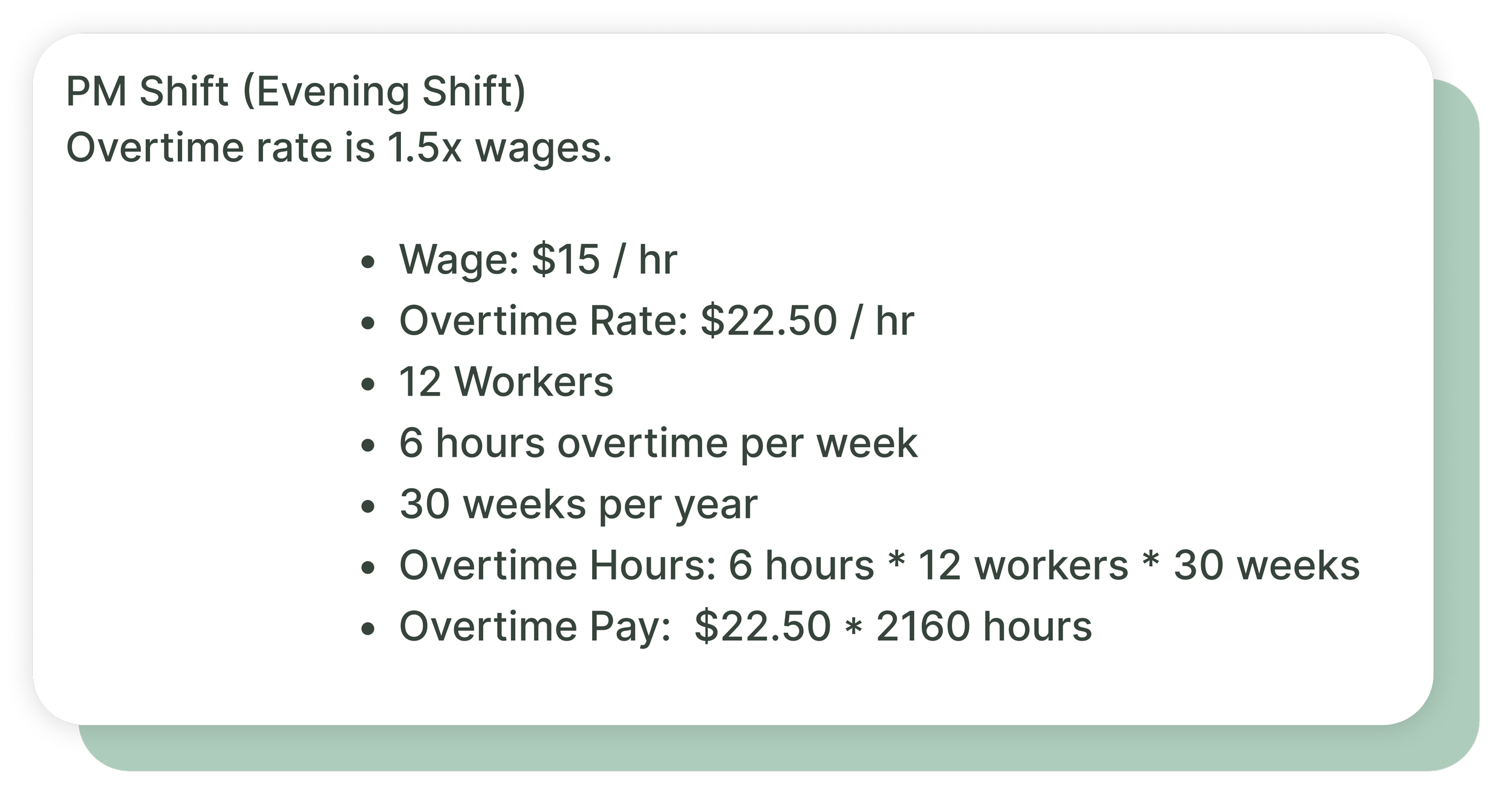

During my time at Marinate, I noticed that overtime during production was a huge problem for the company. Typically, overtime fell on the PM team (evening shift).

When you crunch the numbers…

Over a year that adds up to…

I asked…

How might I help our Ops team at Marinate reduce overtime?

Company Terms / Processes

Let’s get you up to speed…

We’ll pause here and equip you with more context on the operations so you have a base understanding for the problems and solutions.

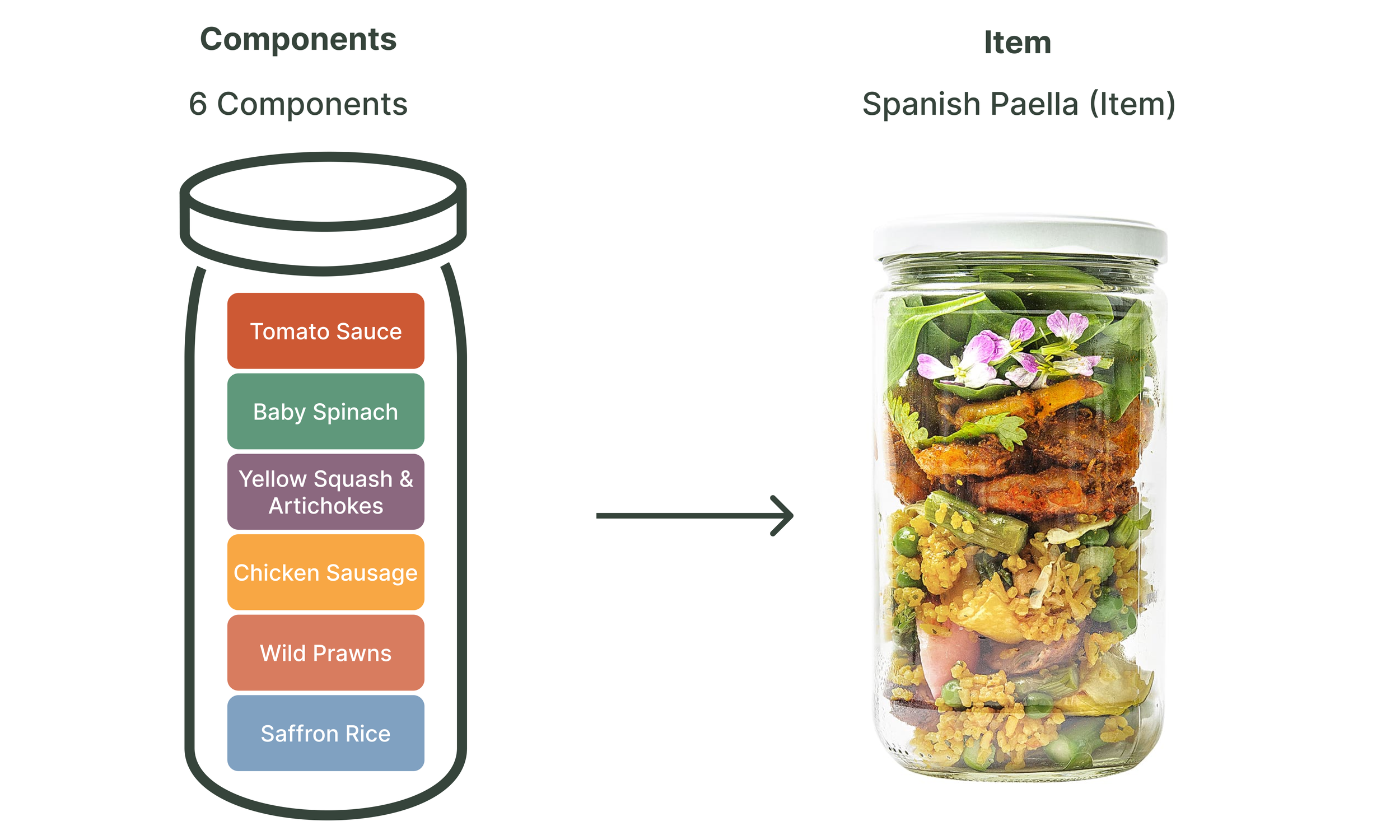

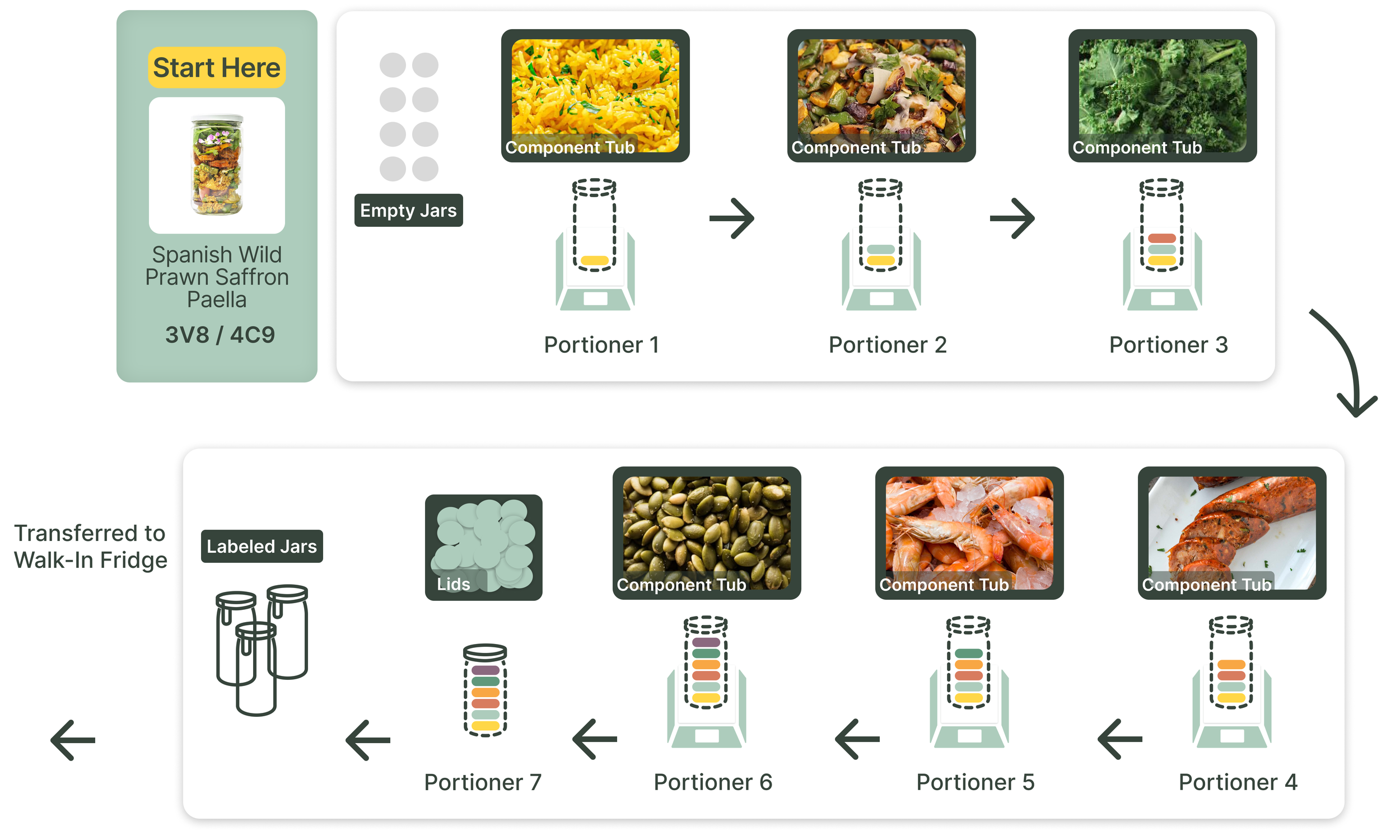

Every item is created in a production line (assembly line)

In this example, we have a production line of 7 “portioners” who are putting together a 6-component item

The first “portioner” in the line will place an empty jar on a scale

Weigh their specific food component in the jar

Jar gets passed down the line (with each portioner adding their component in the process)

Jar is lidded

Labeled

Moved to walk-in fridge

Ops Leads Role

Ops Leads drive the activities of the portioners (workers putting the items together) and ensure all food is assembled accurately and within the deadline before delivery

Now what duties does that involve?

Research

Back to the question…How might I help reduce overtime?

Assumptions

Communication was the main cause of delays. Information was sometimes not captured at all or was inconsistent across communication channels.

Overtime can be fixed by hiring more people. The portioner teams appeared to be understaffed. Ideally there should be 1 portioner for 1 component and often there were not.

Research Goals

• What factors contribute to production slowdown and delays, which ultimately lead to overtime?

• How is specific information captured and communicated between chefs to leads and leads to leads? What channels are being used?

• What information is not captured from current channels?

• What information does an Ops Lead need to start their shift and plan their shift successfully?

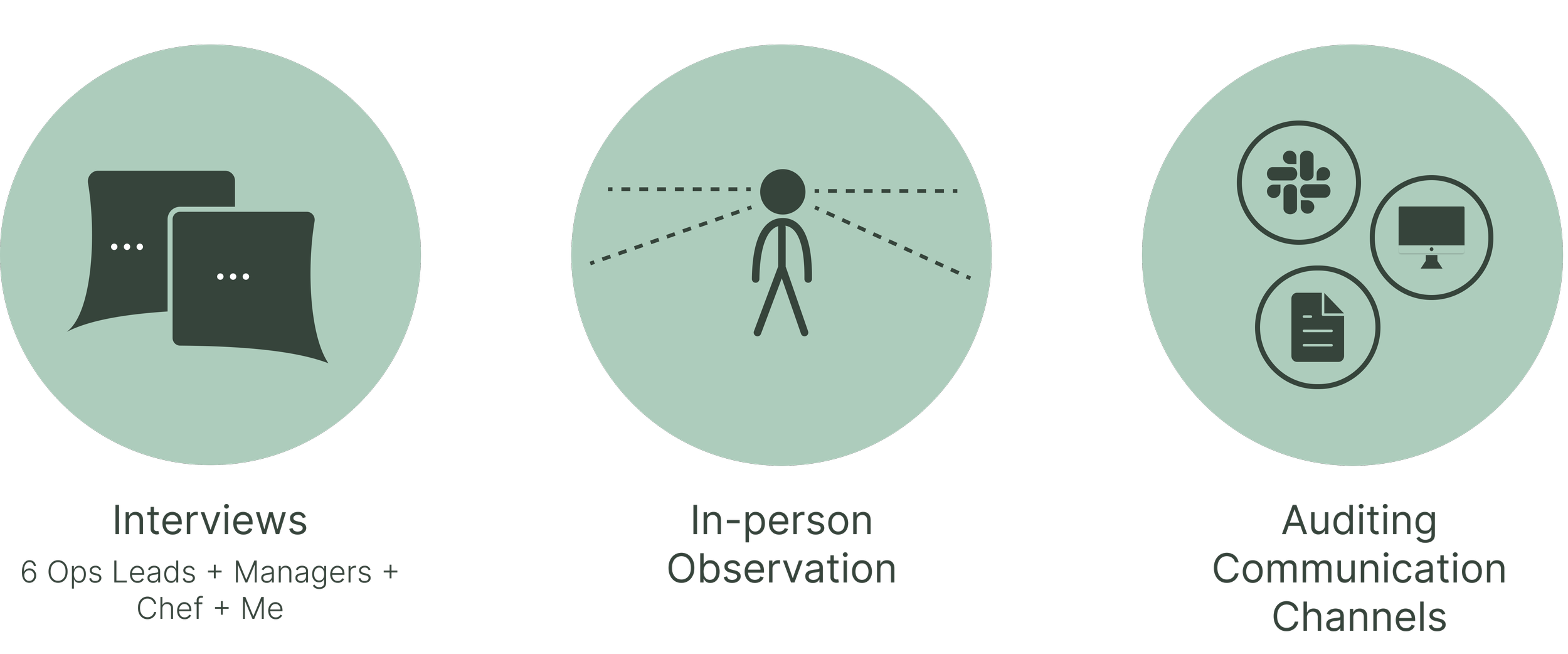

Research Process

6 Core Themes Came Up…

Of the 6 themes, I believed I could have the greatest impact as a designer within……

Poor communication systems across teams & shifts

*The other areas require deeper research, expertise and access to teams that I did not have.

The Problem to Solve

My Hypothesis:

IF I help…

Improve Ops Lead's ability to be proactive and quickly respond to potential issues

Streamline communicating updates, tasks and plans

Reduce the Ops Lead & Chef’s cognitive load

THEN..both teams will be better equipped and aligned to move production forward and meet the production deadline

Problem Statement

How might we rebuild the culinary & ops communication experience during portioning so we can improve the flow of production?

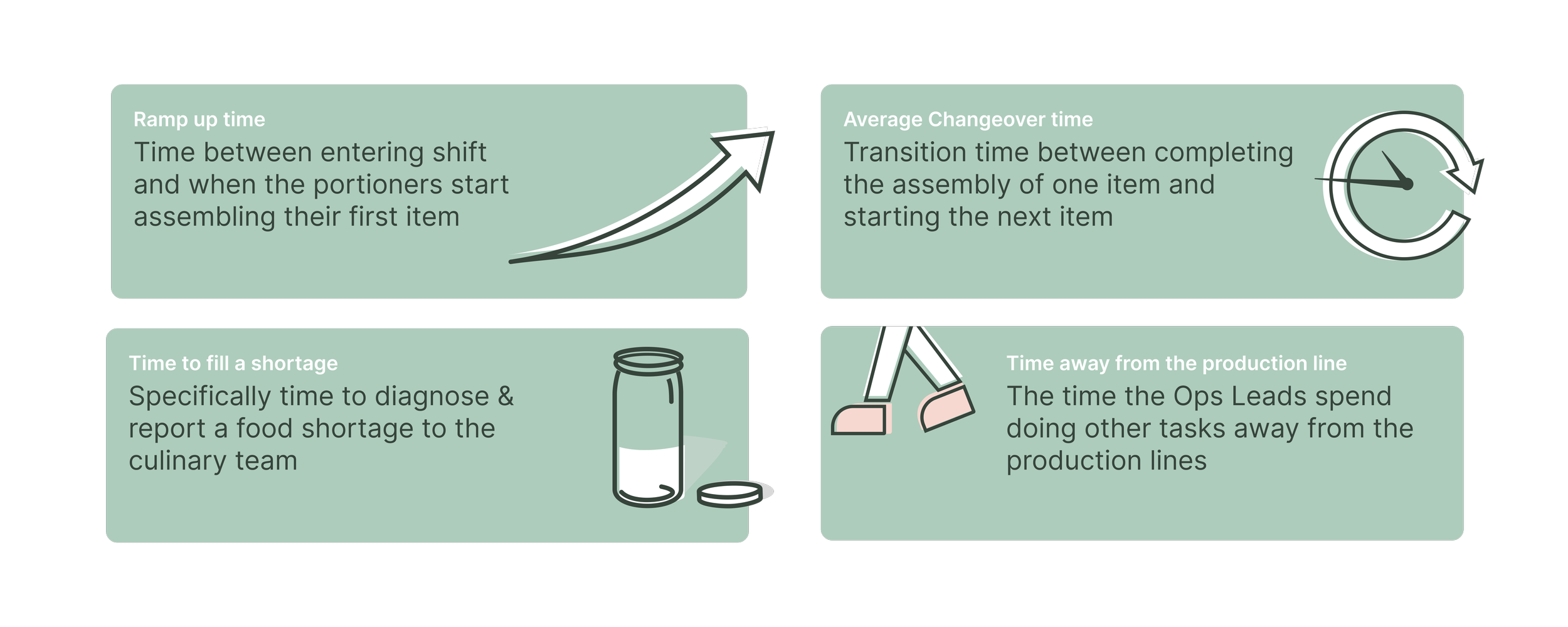

How I Would Measure Success

Reduction In…

3 Core Problems Within Communication System

Siloed Communication Channels

Chefs are “green lighting” items that are not ready to assemble due to task overload

Ops Leads lack an outlet to organize their thoughts & plans for the shift

Problems & Solutions Within Current Communication System:

Siloed Communication Channels

I reviewed 6 channels for communicating information. Ops Leads and Chefs have to manually sync these channels to keep them up to date.

Extra effort is required to review and compare information on these channels because they are physically scattered throughout the 30,000 square foot facility. As a result, some channels are not always in sync.

1. Siloed Communication Channels

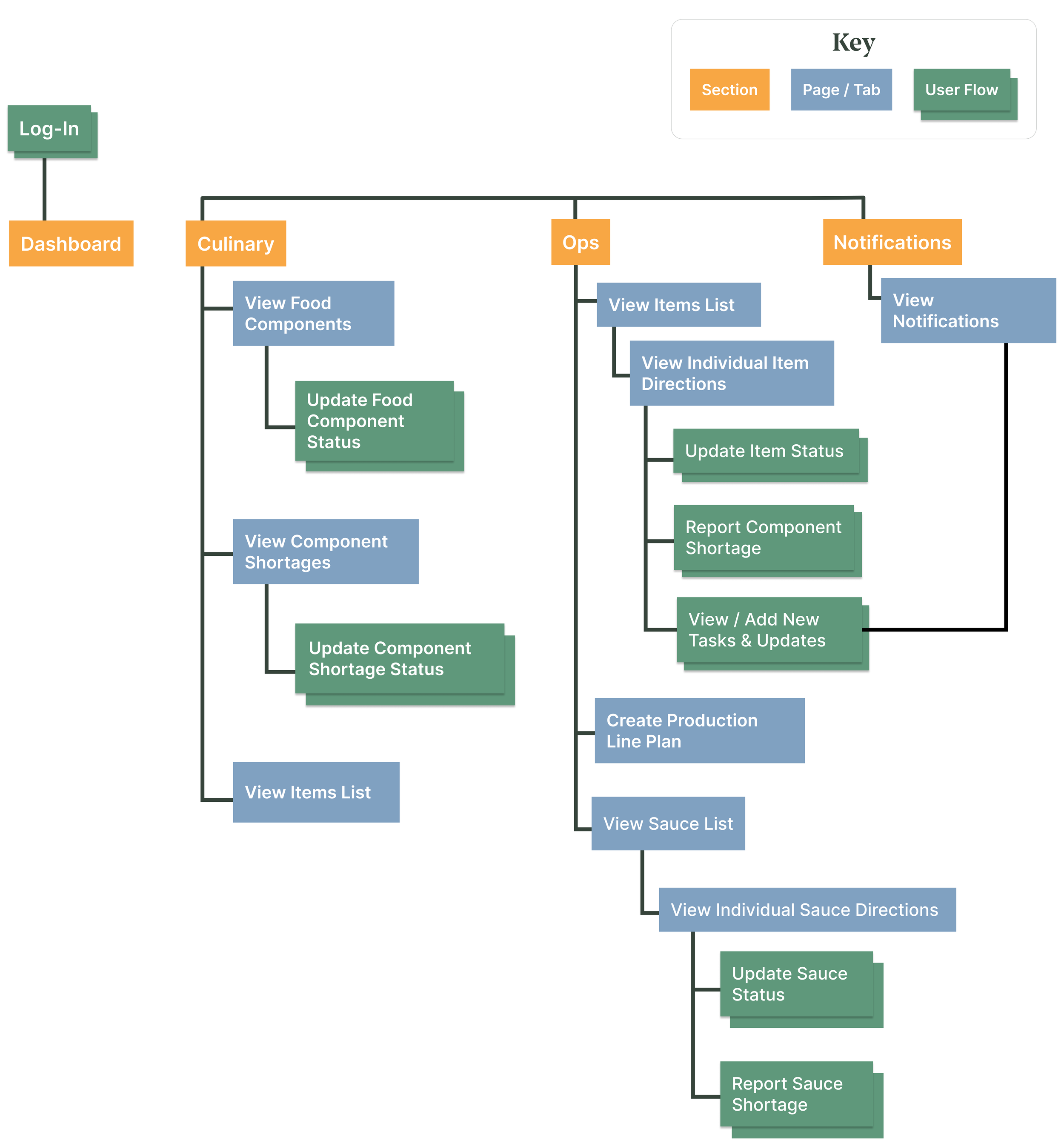

Designing a Solution

I decided to build a mobile application for tablet for the following reasons:

• Unified System - Single source of truth

• Portability- Ops Leads are often on their feet and need to move around the facility

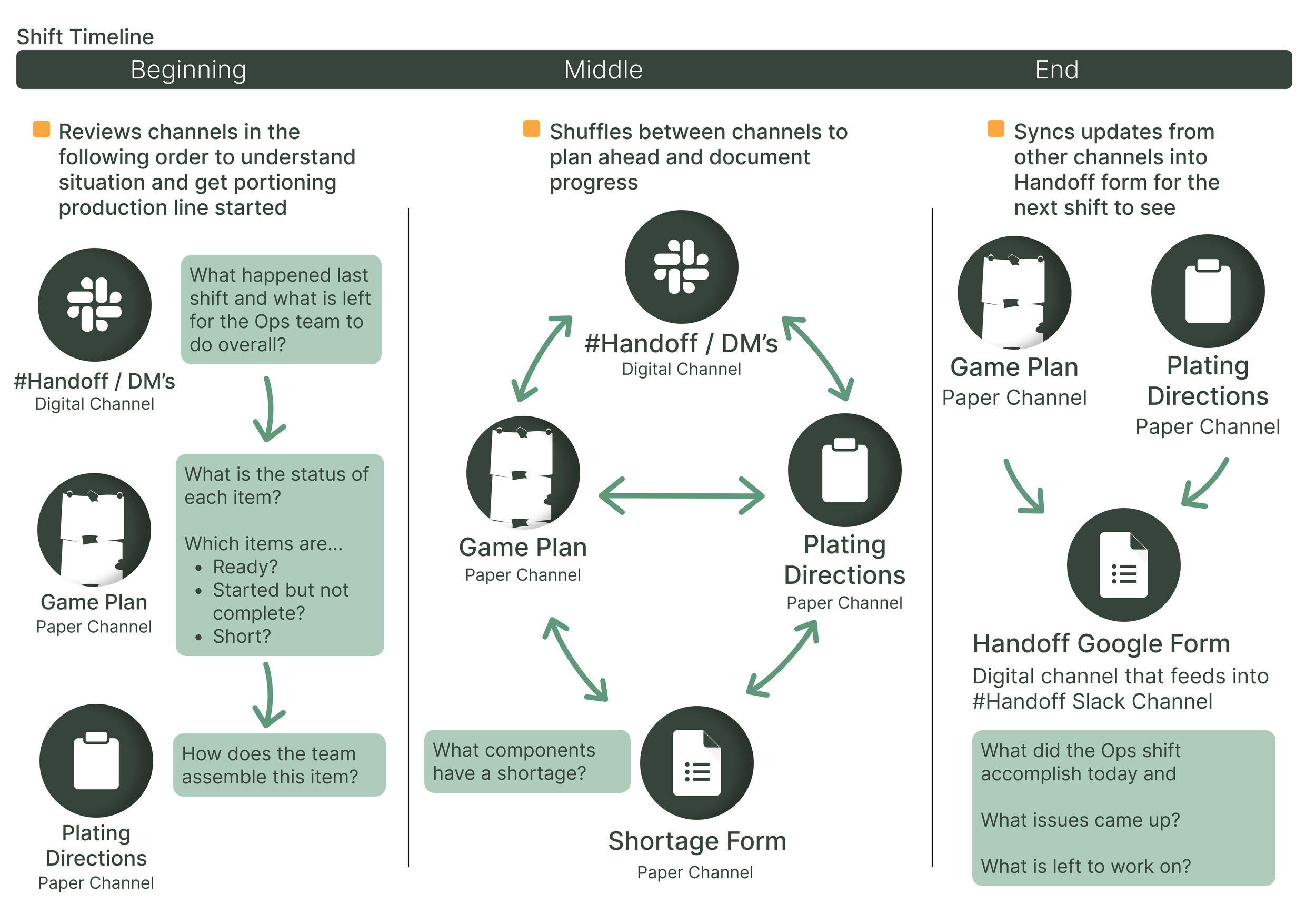

From interviews and observing the Ops Leads, I considered the mental model that the Ops Leads follow when it comes to finding and communicating production information.

This informed how I designed the site map of the app to create a unified system and help solve for silos.

Site Map

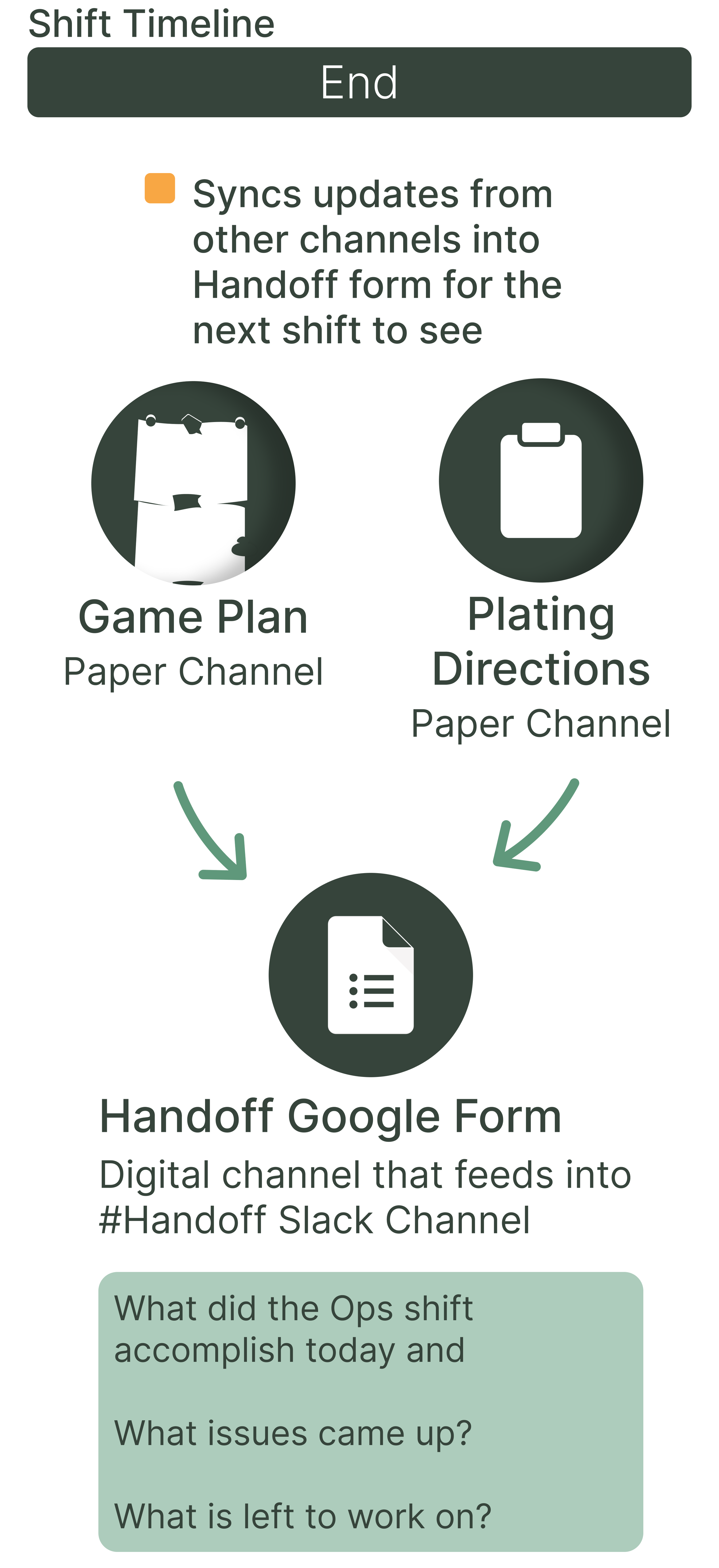

We’ll center our attention on one silo where I focused on removing friction within the Handoff Process

🔎 Handoff: Production Updates that each shift leaves for the next shift

What is the current process for “handing off” information to the next shift?

What solutions did I consider?

Early on, I had a handoff section for Ops Leads to document notes at the end of their shift and see past handoffs…

…then when the next shift’s Ops Leads logged into the app, the Handoff would pop up immediately.

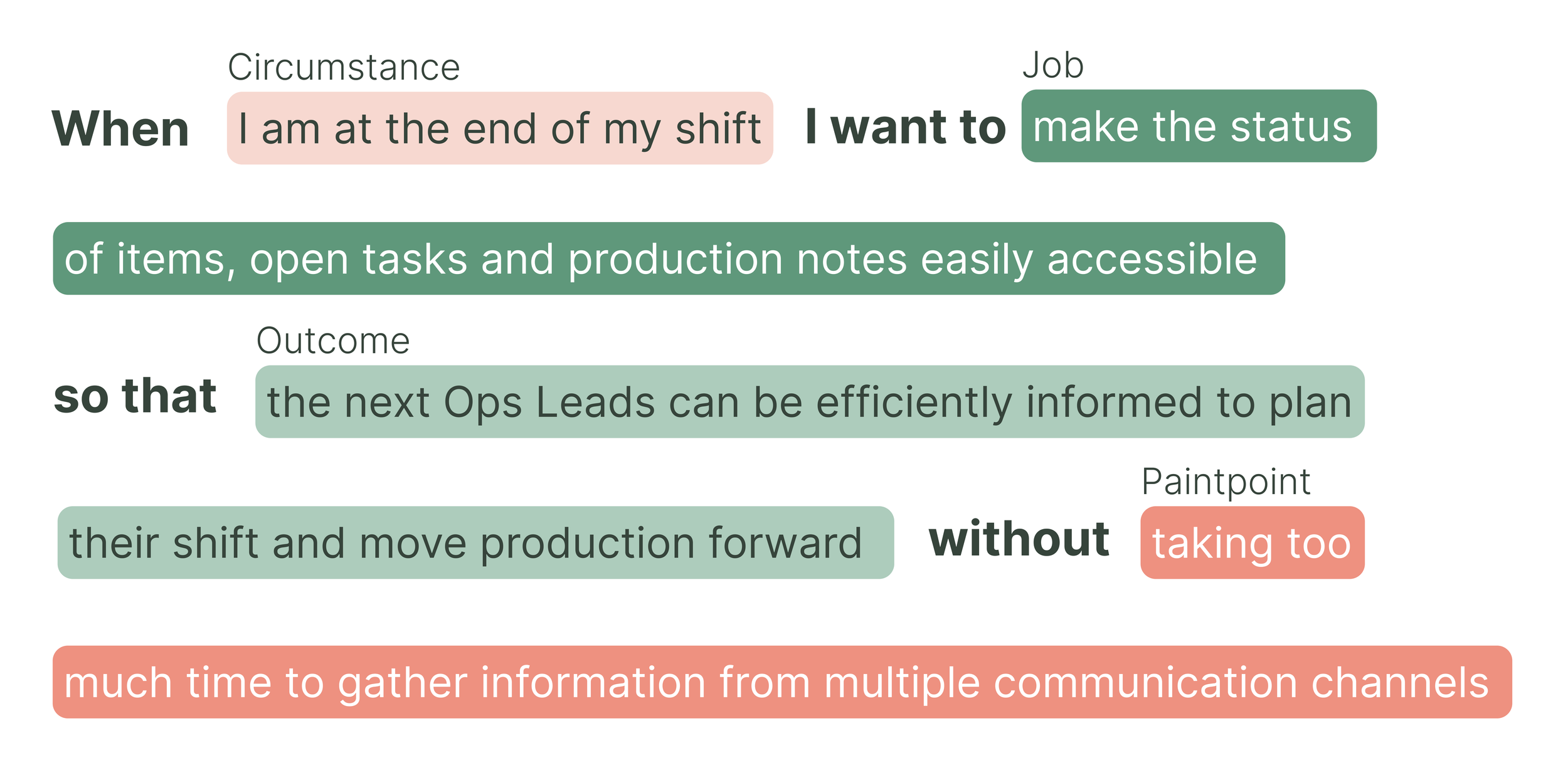

Mentor feedback led me to question if there was still a need for a Handoff section. I thought through what the Job To Be Done is for the Handoff

🔎 Job To Be Done: Framework for understanding the outcomes a user is “hiring” a solution to achieve

Job To Be Done

User : Ops Lead

If…the job is to make item status, tasks and production notes easily accessible

And… I could house this production information under one application

Then…can I organize the information in the app in such a way that there would be no need to have a Handoff section and save developers time from building it?

1. Siloed Communication Channels

Final Solution

To simplify the design, I decided that the job to be done by the Handoff can be delegated to other areas of the app and I could remove the Handoff section entirely to remove redundancy.

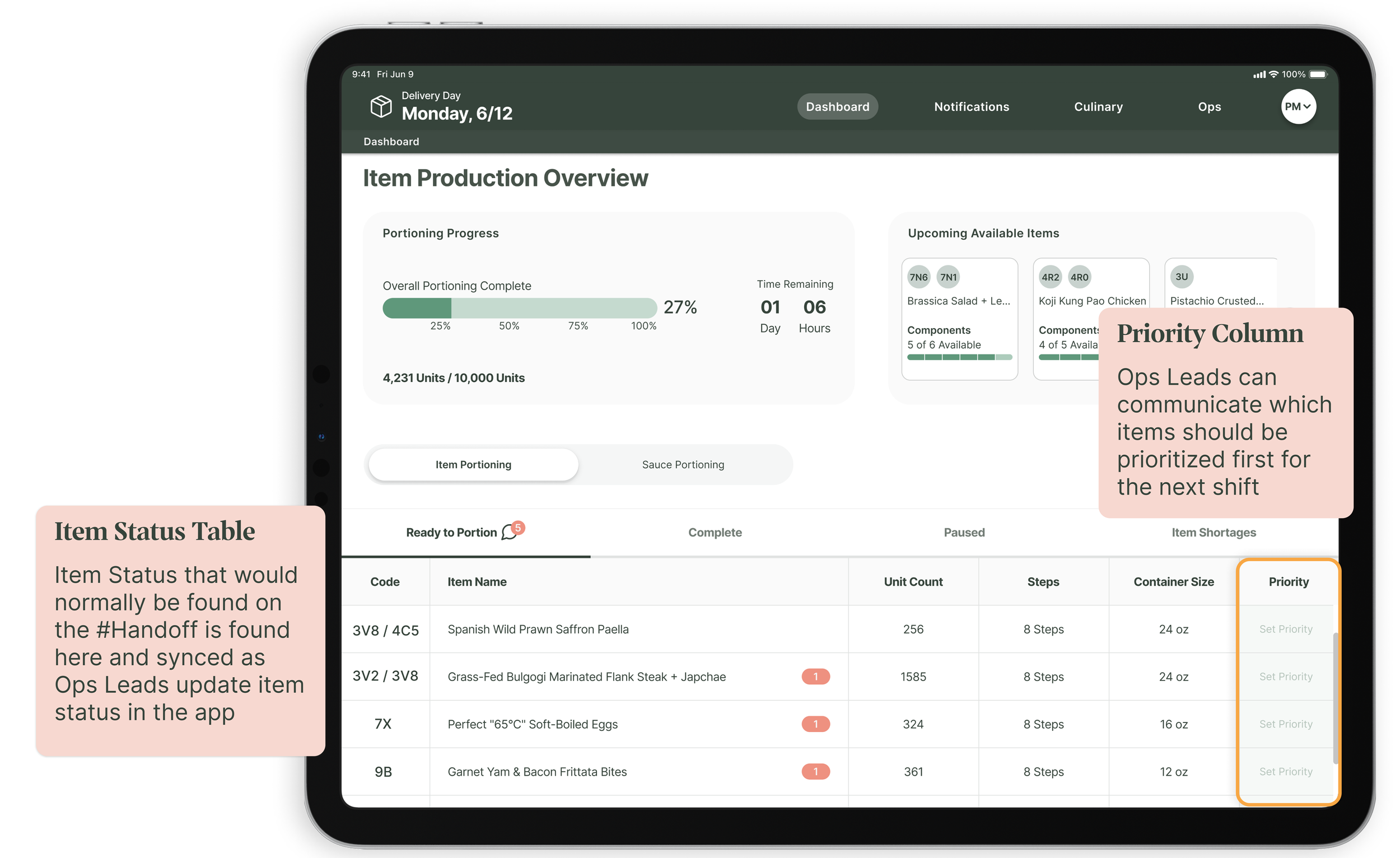

Dashboard

The Dashboard fulfill the job to be done of the handoff by providing an overview of the status of items and what items to prioritize.

Task & Updates Tab

This section fulfills the job to be done that the Handoff had by providing production notes and pending tasks to be completed

Notes are placed within context of the item page itself for easy reference.

Problems & Solutions Within Current Communication System:

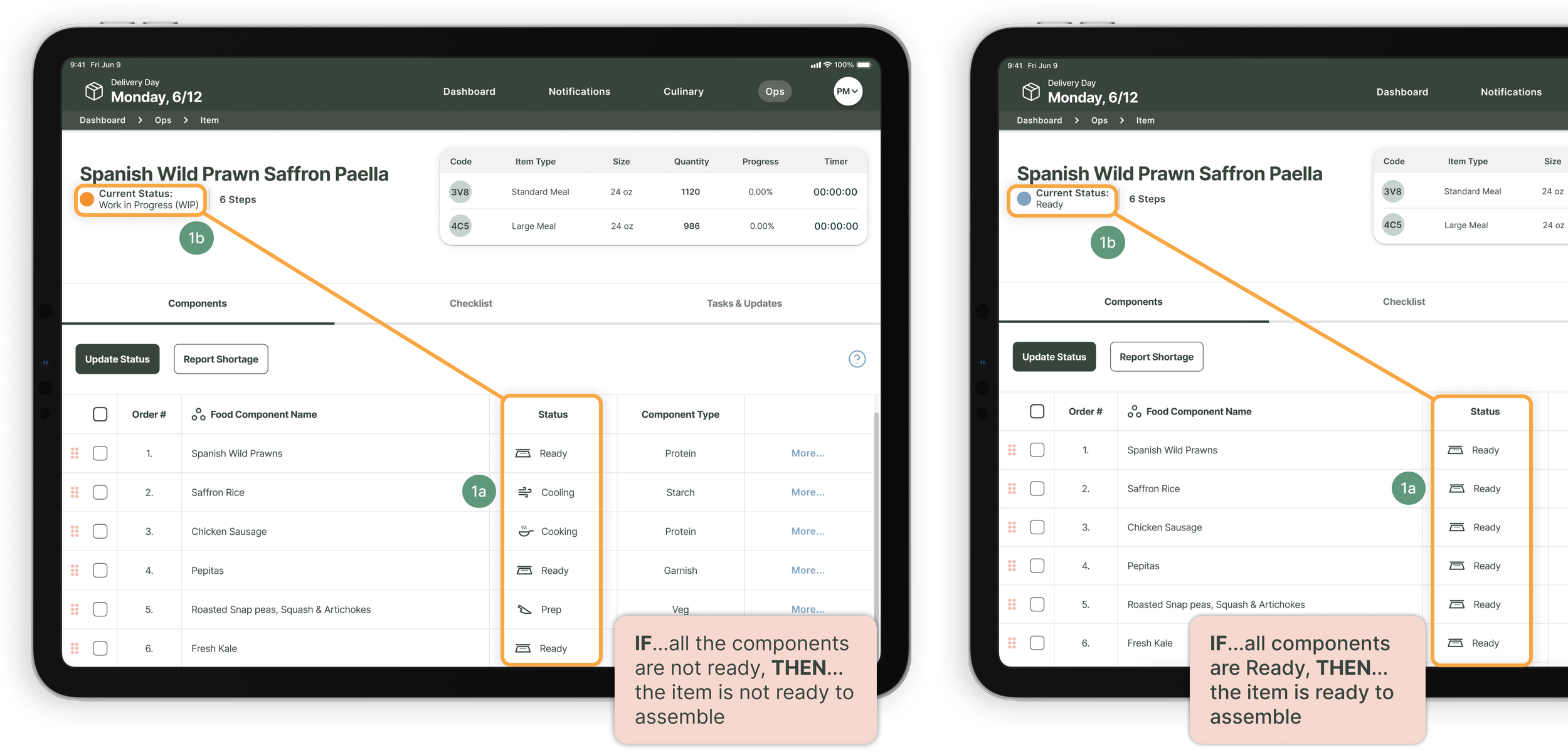

2. Chefs are “green lighting” items that are not ready to assemble due to task overload

🔎 Green Light: Chefs approving items for the portioners to assemble

Typically, a Chef is supposed to check that all components are ready & available before they allow the portioners to assemble an item.

I learned…among the 5 chefs, they are responsible to track the production of…

Result: High cognitive load on the Chefs who are constantly switching tasks in an intense kitchen environment leads to chefs forgetting to check that all components are available before green lighting an item

🔎 Cognitive Load: The mental effort required to process information and make decisions.

2. Chefs “green light” items before they are ready to assemble

Designing a Solution

I asked, what could I take off the Chefs plate to help reduce their cognitive load?

Before

Chefs originally had to keep track of both the status of the food components and Items

After

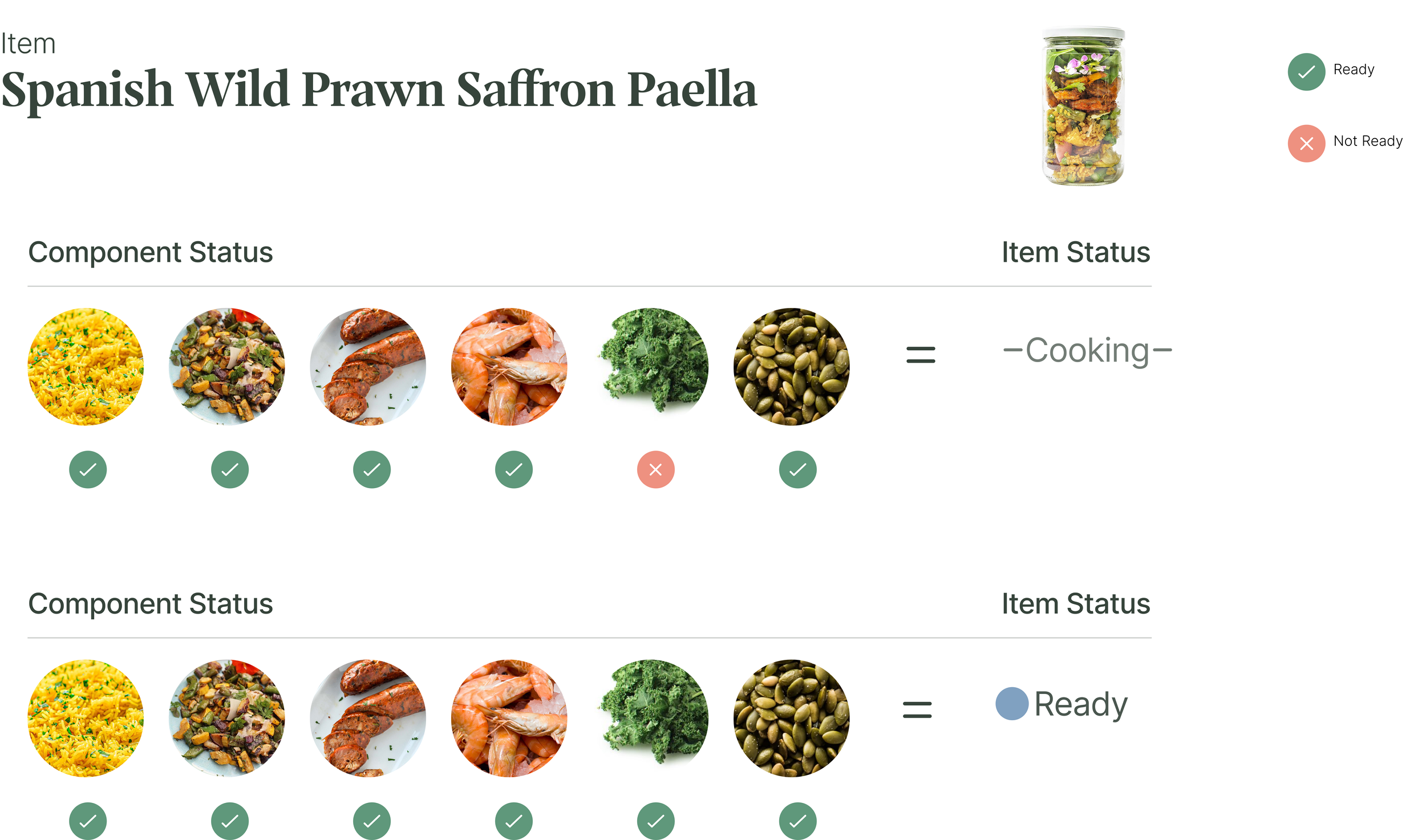

What logic should the system deploy to determine an Item is “Ready to Portion”?

Now Chefs only keep track of food component status and the system will update the status of items for them

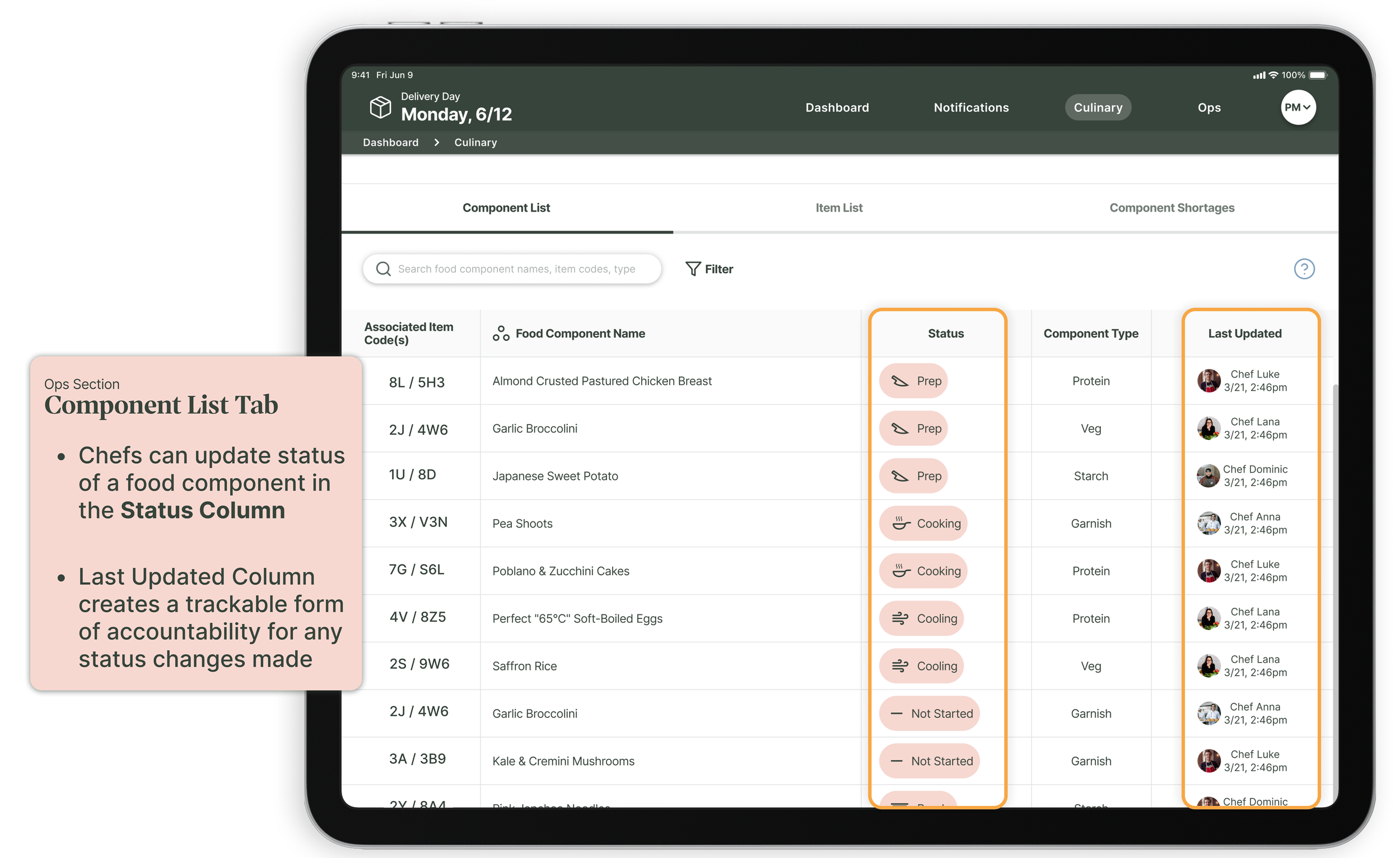

And what does it look like for a chef to update food component status in the the app?

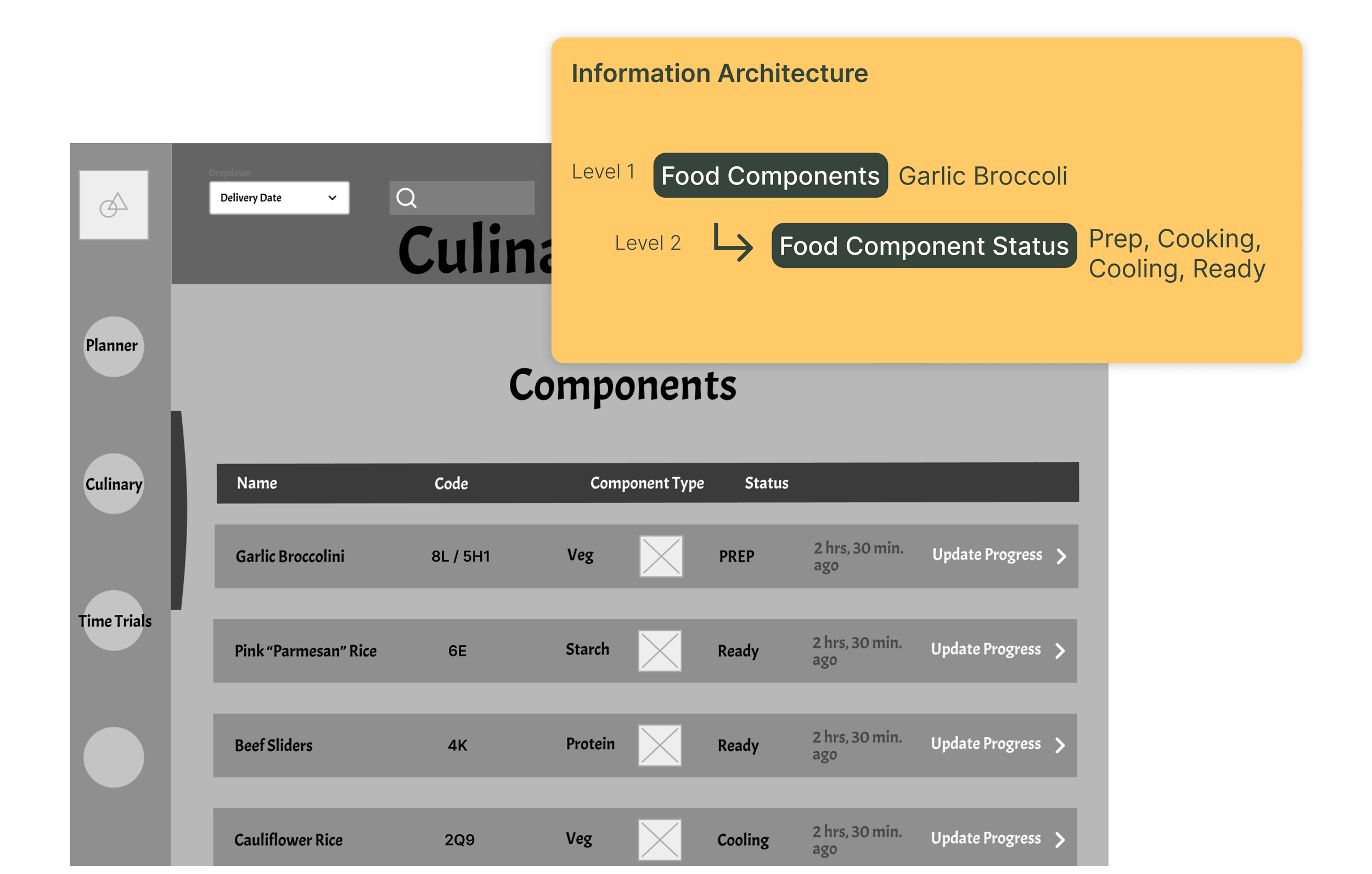

Original Information Architecture

Select item

Select food component from that item

End Goal: Update food component status

Feedback from the Ops Manager revealed that……

Improvement 1

In the next iterations, components are presented first to be more more in line with the Chef’s mental model of how information should be presented to them.

Improvement 2

However, according to Ops Manager feedback, Chefs still need to zoom out to be able to see how far along an item is in production as a whole. This is why the 2nd table exists.

A Chef can then toggle between the 2 tables to see all components or all items

2. Chefs “green light” items before they are ready to assemble

Final Solution

Culinary Section

Item Page

Before Component Update

After Component Update

After a Chef updates the status of a food component…

The Ops Lead can look at the Item page where they will see the the food component’s updated status reflected here (See 1a - Saffron Rice)

And the system will automatically update the item status based on the system logic shown (See 1b)

Problems & Solutions Within Current Communication System:

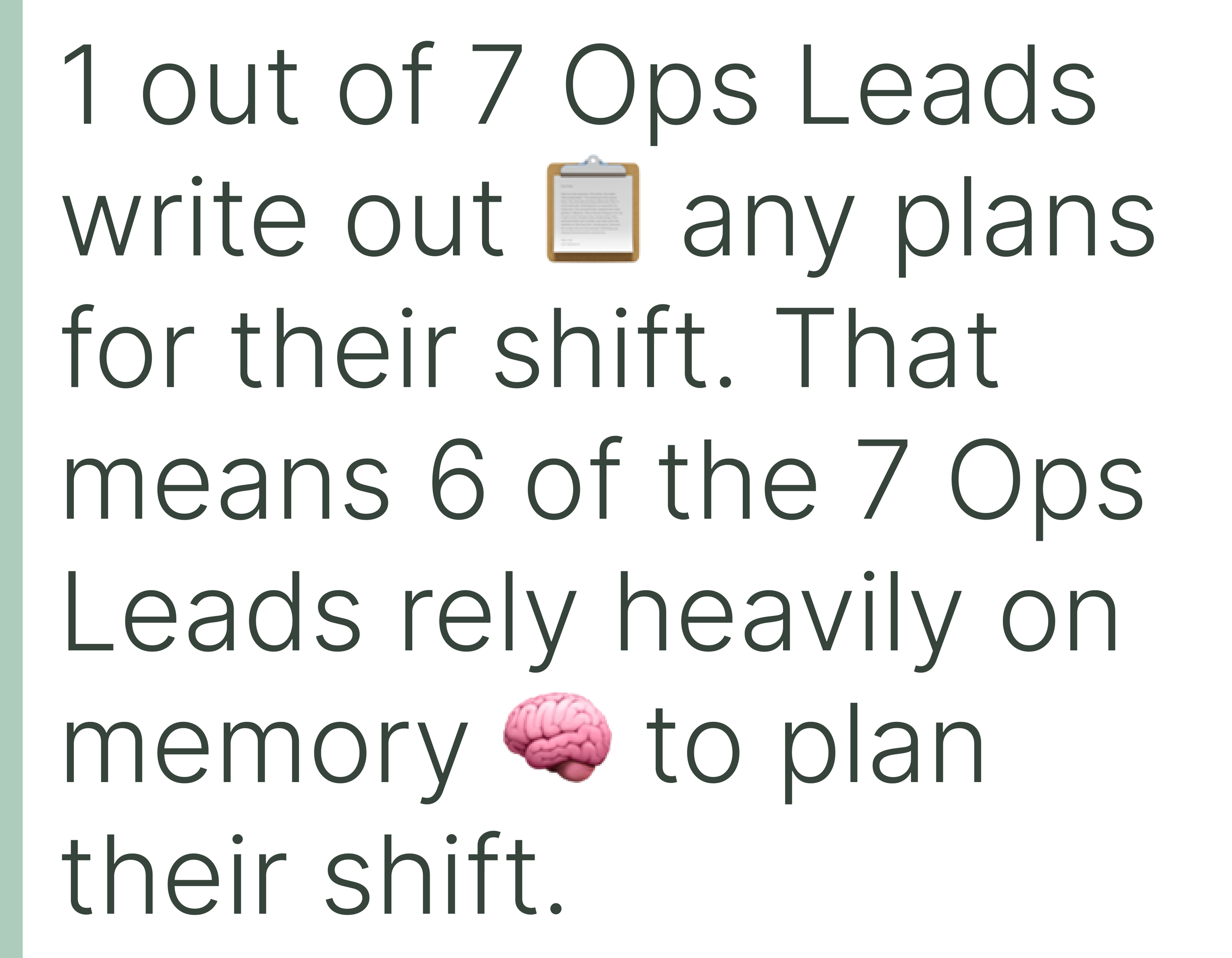

3. Ops Leads lack an outlet to organize their thoughts and plans for the shift

There are many tasks and decisions an Ops Lead is faced with including, but not limited to…

• Balancing shift planning and working on the production line because of low staffing

• Searching for food components in crowded walk-in fridge and around the 30,000 square foot facility

• Pivoting production line priorities when there is a food shortage

Frequently switching between these tasks places a high cognitive load on the Ops Leads

During the 7 month season of high production, I observed a pattern where Ops Leads would get overwhelmed when multiple tasks demanded their attention at the same time in the fast paced environment.

From speaking with Ops Leads, Ops Managers, and my own experience I documented those tasks. One of those tasks is to plan the shift for the portioners.

3. Ops Leads lack an outlet to organize their thoughts and plans

Designing a Solution

I hypothesized that If we could help better organize the Ops Leads’s thoughts and plans, then we could free up some of their working memory to focus on other tasks.

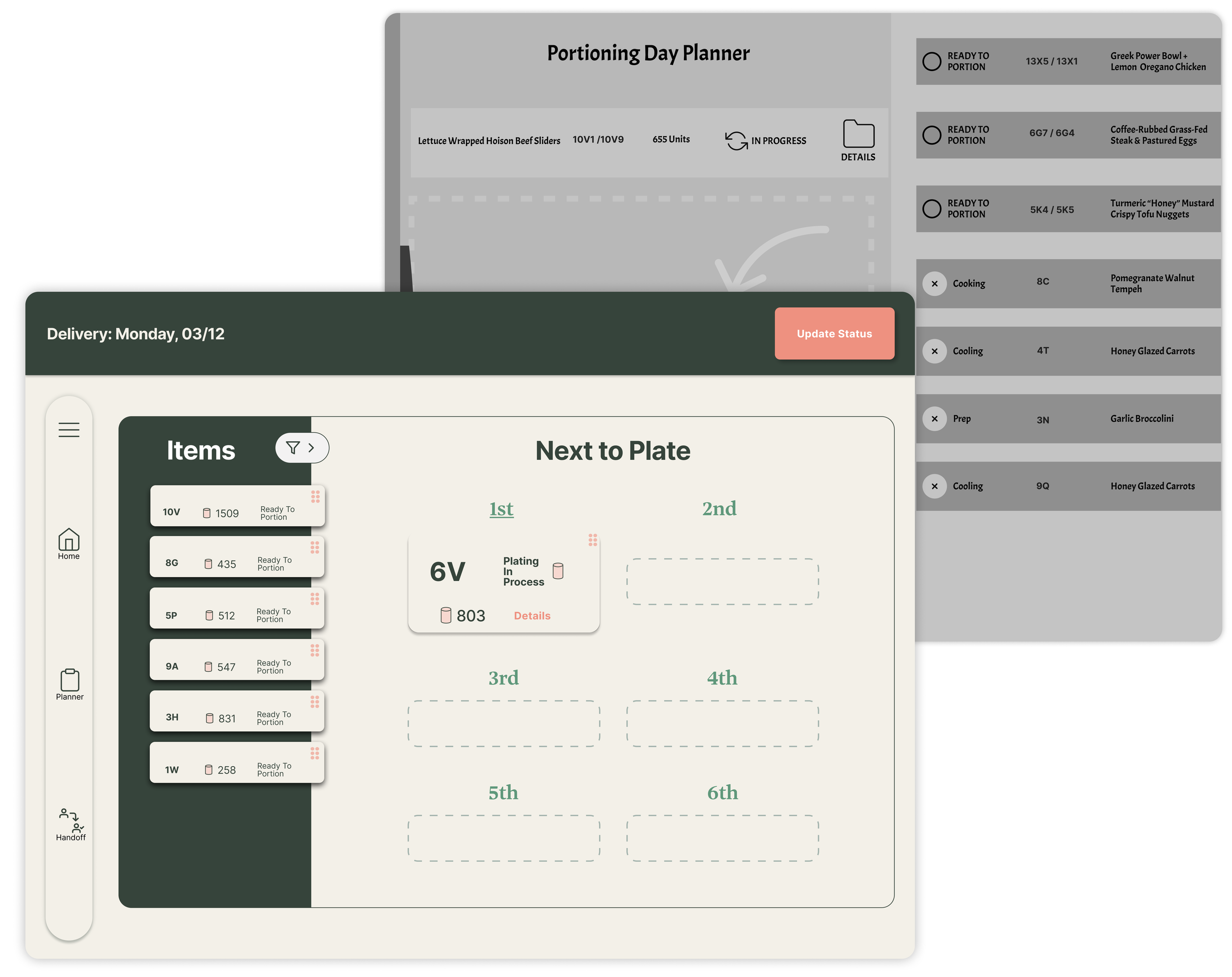

Planner

“Drag & Drop” Items to build a production plan for the shift

User Testing and mentor feedback indicated that people did not know how to interact with the design and that it was unconventional

Since there were no easily accessible food logistic apps, I looked at productivity management apps such as Notion, Monday & ClickUp to better understand design conventions including:

• Table visual layouts

• Comment & Messaging Sections

3. Ops Leads lack an outlet to organize their thoughts and plans

Final Solution

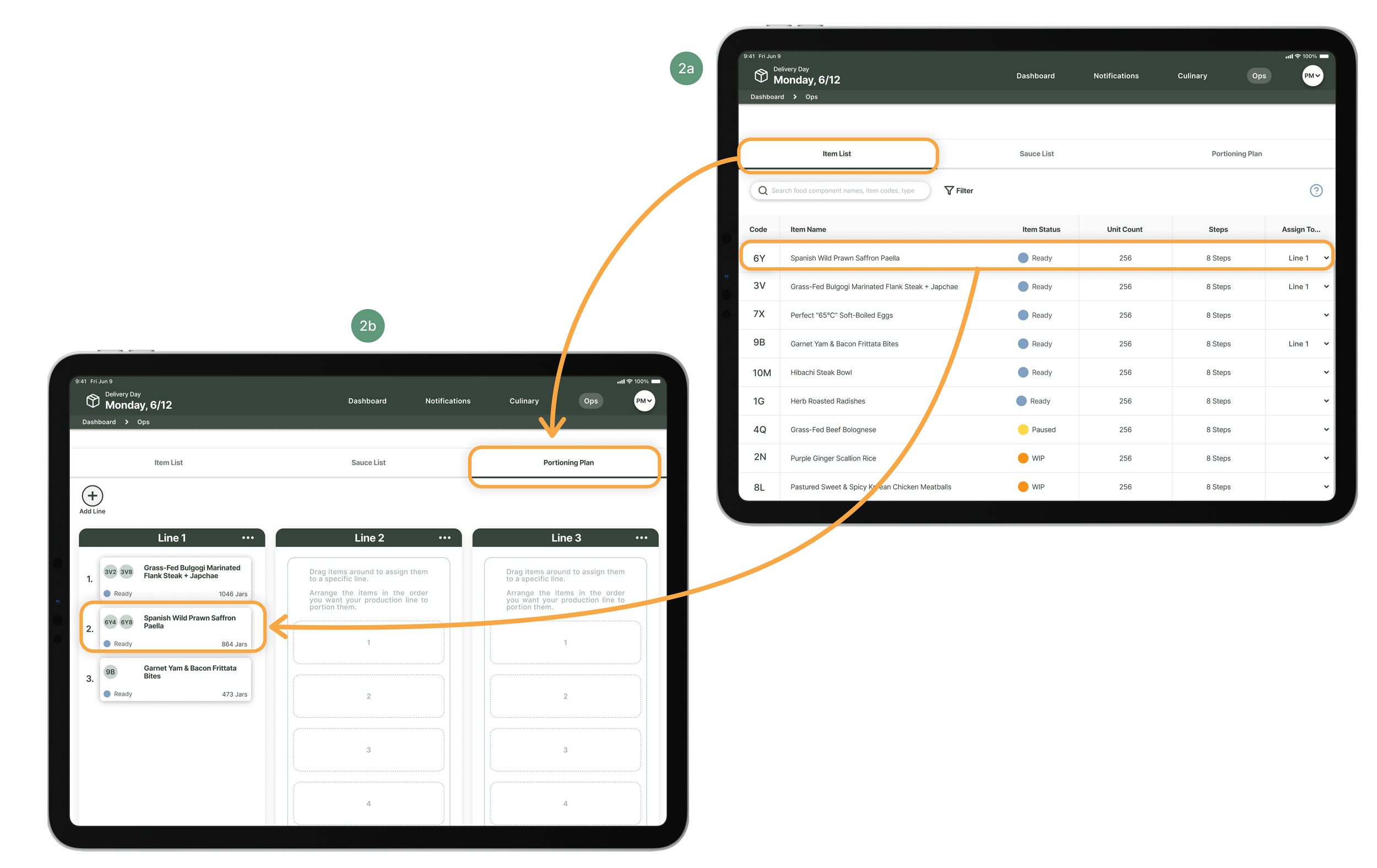

In the the Item List tab, assign an item to a specific production line - (Spanish Wild Prawn Saffron Paella to Line 1) - See 2a

When the Ops Lead switches to the Portioning Plan tab, they can see that the Spanish Wild Prawn Saffron Paella was added to Line 1 - See 2b

The Portioning Plan gives the Ops Lead a space to visually plan the production lines.

🛠️ Functions:

• Drag and Drop items into different production lines

• Swap the order in which items will be assembled in

• Add another production line if needed

Prototypes

Let’s take a test drive

Job to be Done

User: Chef

Job to be Done

User: Ops Lead

Reflection

Lessons

Point > Polish

During the design process, I would try to make things super polished before getting feedback from a mentor. What would happen is that there would be so many changes to make that it didn’t make sense to over polish the iteration. The lesson is to design with enough fidelity to make your point clear but not over polished.

Lay a foundation of context

In order to get quality feedback, I had to improve how to clearly communicate context. My mentor had no idea of the company’s processes and terminology and so I had to equip him with the knowledge and research so he could better critique my thoughts and designs.

Other Deliverables

For the curious minded…

*Please reach out if you would like to see these files